FRAM is Norway's only manufacturer of Master Links and Master Link Assemblies. We are a significant supplier to the oil and aquaculture industry in Norway. Our products exceed the requirements for the offshore industry.

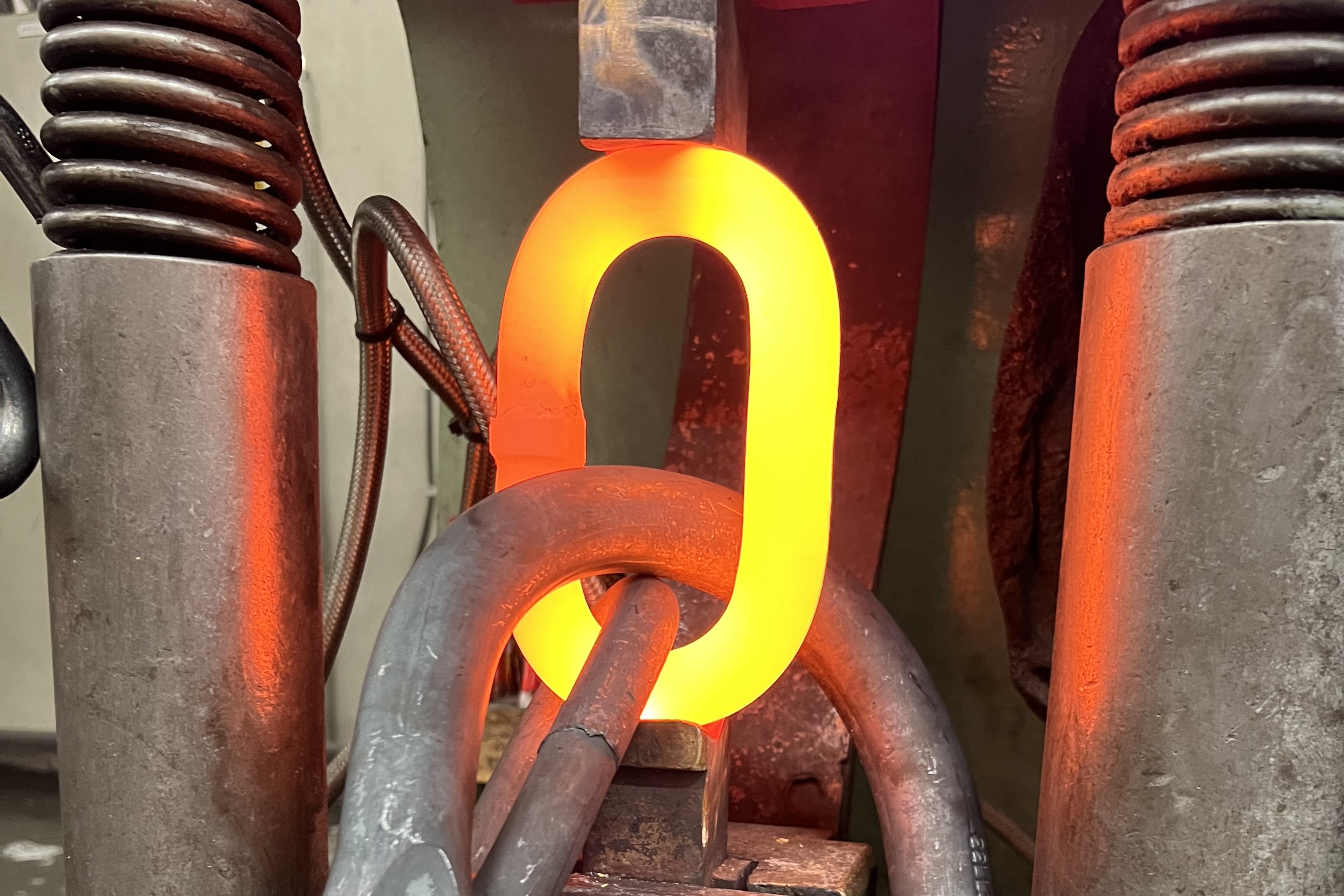

FRAM has developed its own steel composition together with the best steel mills in Europe. We collaborate with the best steel mills in Europe to obtain the best steel quality. FRAM exclusively uses a peeled surface on the material for the Master Links, so we remove surface defects that will always occur during normal production of bar steel - the result is optimal quality with minimal surface cracking.

FRAM Offshore Master Links are supplied with a powder-coated surface.

FRAM has a high production capacity and good stock. This means that we usually have a short delivery time.

FRAM performs testing on 100% of Master Links in accordance with NS-EN 1677-4.

FRAM chain slings are according to NS-EN-818-4, and can be delivered with connecting links or fully welded. FRAM welded chain slings are produced up to 32mm chain. Welded chain sling can also be delivered according to DNVGL 2.7-1 up to 23mm chain. FRAM chain slings are tested and certified.

FRAM has many different hooks and shackles modified for ROV operations. WLL from 2,5 tons and up to 300 tons. Tested and certified.

In addition to our product scope of supply, we specialize in the design and manufacture of special lifting equipment. Examples of special equipment are yokes, rings and master links adapted to crane hooks, special hooks, plate fittings, etc. When standard fittings can’t be used without endangering the safety of personnel and / or goods, we are authorized to design and certify customized fittings. We specialize in fast construction and manufacture of such fittings in close cooperation with the client. Special lifting equipment is delivered with certificates in the same way as standard equipment.

A comprehensive series of quality control tests are implemented in all phases of production as well as final acceptance of finished products. These tests measure strength, Impact toughness, transition temperature, chemical structure of the steel and each individual link has to pass a load test. 100% testing is also carried out on each link after a pre-determined time period post galvanization.

The factory is approved to ISO 9001:2015 standards, with production routines certified to requirements for NS 9415. We also hold additional documented approval related to equipment and procedures required for other areas of the offshore industry. All products have trace marking and can be traced back through the production process and to the material used.